The Fake Cartier ID Two Concept Watch

The Cartier ID Two Concept Watch – Complete with a transparent monobloc ceramic case and 32-day power reserve.

The most beautiful thing about mechanical wristwatches is that one can love them for so many reasons – and in many cases, for diametrically opposed reasons. For example, I love the Rolex Submariner of the 1970s for its perfect proportions, the seemingly endless list of exploratory firsts for which it was replica watches summoned, and the way they have the ability to age with time better than arguably any other wristwatch. I love the MB&F Horological Machine 2 for the sheer audacity of the design, the magnitude of construction (which, for those who haven’t had the pleasure, is like it was built from a two-ton erector set made of solid gold and titanium), the creativity and finishing of the movement, and what I think pieces like those from MB&F mean to the wristwatch industry – an industry that seems to be written off on an almost yearly basis by uninformed journalists that view the success of the iPhone as proof that people don’t care about mechanical watches anymore – when all they’d have to do is look at the numbers to see interest (and sales for that matter) is stronger than ever. The watch I am writing about today I also love, but I don’t love it because it was worn by Steve McQueen like the Rolex – in fact no one has worn it, and no one ever will, because it’s a pure concept watch never to be produced in serial. Still, I love it because it could very well be the singularly most important timepiece for mechanical watchmaking, as a whole, over the next generation – and it comes from Cartier.

Certainly, the MB&F’s of the world push mechanical watchmaking forward, but so do many larger, more conventional manufactures that the public often thinks of as building rather common timepieces. For example, TAG Heuer, known to many as a mall watch brand, has a truly superb R&D department and they continue to push the idea of high-speed chronographs forward – something that appeals to more than just the “watchnerds” among us as evidenced by the now 218,000 unique views of this video we shot of the Mikrotimer last September). But even more dedicated to the future of watchmaking as a whole is Cartier, though most wouldn’t know it. Cartier’s less expensive watches are more than ubiquitous to many of us – to borrow a line from my friend Wayne Campbell, – Everybody in the world has a Tank Francaise. If you lived in the suburbs, you were issued it. It came in the mail with samples of Tide. (Not really, but you know what I mean.)

The ADLC titanium coated movement of the Cartier ID Two – A little different than what you’ll find inside a Tank Francaise

But, on the opposing side of the North Shore Sweet Sixteens with a tank on their wrists sits Carter’s Fine Watchmaking Division – what is rapidly becoming one of the most impressive horological labs in the world. Since its inception, Cartier has produced a full 19 new calibers, including the fantastic minute repeater shown at SIHH 2012. At the peak of the FWM division is something called the “ID” program, which stands for “Ideas + Development,” and it acts as a relative think tank for watchmaking in general. The goal of the ID program is to conceptualize what mechanical watchmaking will be like in the decades to come, and what advances will really matter.

In 2009, Cartier introduced a watch called ID One. It was the very first watch in the world to be completely adjustment and lubricant free – meaning it could, in theory, work in perpetuity. Why would a lubricant free movement create a “timeless” watch? Well, as Abraham-Louis Breguet once famously said “Give me a perfect oil, and I will give you a perfect watch.” It is the oil that keeps a watch running, and over time, the oil will lose fake Cartier its characteristics and cease to ease the friction inherently found in the gears of a mechanical watch. Cartier removed the oil from the equation completely via a manufacturing technique called “DRIE” (deep reactive ion etching) which allows precision cutting to the nearest micron, geometrically reorganizing the escapement and using a variety of purposefully engineered materials (carbon crystal, niobium titanium, ADLC and the like). You can see more on the ID One in this video here:

Why does this really matter though? It matters because it created a watch so precisely constructed that zero adjustment was required during assembly. You might think that “adjustment” is just some tinkering done by the watchmaker before dropping the watch in the box to go out to the store, but in actuality, adjustment takes up 30% of the time required to sufficiently assemble a watch. The ID One was completely insensitive to shock, change in temperature, and magnetic fields. The lubricant-free ID One was a big deal, and just two days ago at Cartier’s La Chaux de Fonds manufacture, we joined CEO global head Bernard Fornas for a presentation of the Cartier ID Two – a concept watch from top to bottom.

The ID Two

The ID Two

Where the ID One’s innovation was centered around the optimization of the regulating element, the ID Two’s genius is that it re-thinks what a watch can be from the ground up – from what the case is made of (a single block of ceramic called Ceramyst that is completely transparent – sorry Richard Mille) to its power reserve (32 days – sorry Lange) to the way the caseback is held on (it uses a vacuum seal – not a single screw…seriously). Essentially, Cartier, drawing on inspiration from the automotive industry, has created the world’s first energy efficient timepiece. Why? Well, mechanical watches are ultimately horribly inefficient machines, wasting, on average, 75% of their stored energy.

With the ID Two, the goal was to increase the amount of stored energy in a given space (the springs in this watch are not abnormally long like they are in the Lange 31, while decreasing the amount of energy consumed by the oscillator – and working backwards – to ensure the energy transferred from the barrels to the escapement is maximized. The result is a watch that produces 30% more power and consumes only half as much as a traditional watch, providing for a 32 day power reserve in just a 42mm case. But how, exactly? Watch the official video for an overview, and then read on:

There are three problems of the traditional mechanical wristwatch that that the Cartier ID Two addresses. Here we’ll run you through them all:

Problem One: How To Store The Most Energy Possible?

Most mainsprings are constructed of metal. When coiled up, they rub against each other, and this friction causes the watch to deliver much less energy than is being stored. In the ID Two, the springs are, for the very first time, made of fiberglass. Configured as twin barrels on two levels, fiberglass has the ability to store much more energy than metal – which is why, for example, pole-vaulters use fiberglass poles. The springs are also covered with an ultra-thin layer of pore-free, transparent polymer film, removing the need for lubricants completely. The barrels themselves are coated in ADLC so they are very hard and smooth, and these two dual-level barrels with their four fiberglass mainsprings can retain 30% more energy than a traditional barrel.

Problem Two: How To Transfer That Energy From The Barrels To The Oscillator?

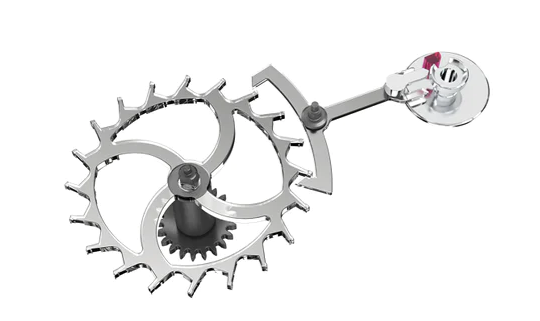

So, even if you are able to store more power, all would be for naught if you weren’t able to transfer it efficiently to both the gear train, which drives the hands of the watch, and the oscillator, which regulates the watch. To ensure the highest efficiency in this process, Cartier has completely reengineered both the configuration of the gear train, and from what it is made. The gear train in the ID Two is no longer linear, with a central wheel accompanied by moving shafts orbiting around the center together with the gears and pinions to which they are fixed. This “planetary” architecture allows for smaller teeth-loads and higher rates of transfer between gears. And about those gears – they are no longer steel and brass, but rather carbon crystal-coated silicon, which is entirely anti-magnetic, anti-corrosive, shockingly smooth, and 60% harder and 70% lighter than steel. All this accounts for 1/5th the friction you could expect in a normal watch’s gear train.

And then there is the escapement. In the ID Two, both the anchor and the escape wheel are constructed of carbon crystal and manufactured using DRIE technology down to a single micron, so the fit is quite literally perfect.

Problem Three: How To Minimize Consumption?

First, Cartier used the Carbon crystal oscillator with Zerodur®2 hairspring that they pioneered with ID One. But the lightweight oscillator wasn’t enough. Cartier determined that of the power lost by the oscillator, only 20% of of it was due to friction, while the other 80% was due to the resistance found in the air. The only way to remove this air friction was to remove the air from the case – and that’s exactly what they did, with a high powered vacuum sealed case. Constructed from a single block of Ceramyst – the first polycrystalline transparent ceramic, this allowed the case to be built in just two parts – the case, and the caseback, which allowed for just two sealing areas – the case-back and the crown. The case is vacuum sealed at 99.8%, meaning there are 500x less air particles in this case than in the normal atmosphere. There are no screws for the caseback as it is held on with the vacuum seal, and the solitary gasket has been “doped with nanoparticles” (I was doped with nanoparticles once too, in college). This AirFree technology allows the oscillator to consume 37% less energy than in a traditional watch.

So, the Cartier ID Two Concept Watch, compared to a traditional mechanical watches holds the following (ridiculous) attributes:

stores 30% more energy in the same space (using the barrel with double fiberglass springs)

consumes 37% less energy from the oscillator alone thanks to the vacuum seal

contains 500x less air inside the case

was manufactured to 1 micron (1/1000th of a millimeter) for many components

took five years of research and development across 135 different engineers

is the source of six patent applications

holds 32 day power reserve in a 42mm case

consumes half as much energy as a whole watch

The Coolest Watch You’ll Never (Have The Chance To) Own

The Cartier ID Two, when shown to a select group of international press earlier this week, changed the conversation on what we can expect from mechanical watches moving forward. The concept of a high-efficiency mechanical watch only makes sense, and it is Cartier that showed the world how it might look. The vacuum replica watches uk sealed case, made possibly only by the design of the lubricant-free movement, is genius. The use of fiberglass springs, the entirely new design of a gear-train, as well as the incredible manufacturing technique make the ID Two a true glance at the future of watches. What is most interesting about this watch is that there is not a complication, there isn’t even a a power reserve display (and you’d think there would be because it has a 32 day reserve). Why? Because this watch will never be commercialized. No form of the ID Two will ever be made for sale, at any cost, to anybody, just like the ID One. This is painfully frustrating to me, but Cartier believes that the ID watches are more of an intellectual exercise than anything. Parts of the ID Two will be used in production pieces in the not too distant future, but after they are further tested and improved. It may take many years to see some of what we saw earlier this week in the ID Two come to market, but that’s OK. If the ID Two is any indication of what Cartier has in store for us, we are just now entering a great period for watches, and our guess is, this watch, seen first right here, will be studied by the entire industry for a long time to come.

Editor’s Note: We will be back in the coming days to show you live photographs of the Cartier ID Two. Stay tuned till then!